2019

TOPECH Anti Friction Organic Additive

Very yellow high-transparent fully oily liquid, Organic additive is the modification of C 60, the modified fullerene produces polarity and binds with N-Mo to form Organic Fullerene, which completely dissolves with lubricating oil.

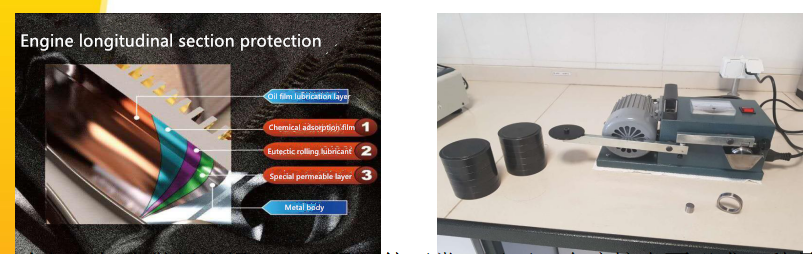

This new type of unique lubrication structure is the first to create chemical adsorption film, special element penetration layer, eutectic rolling lubrication layer multi-element lubrication mode, to improve the extreme pressure anti-wear performance.

It is one of the longest representative technologies for the longest duration of anti-wear!

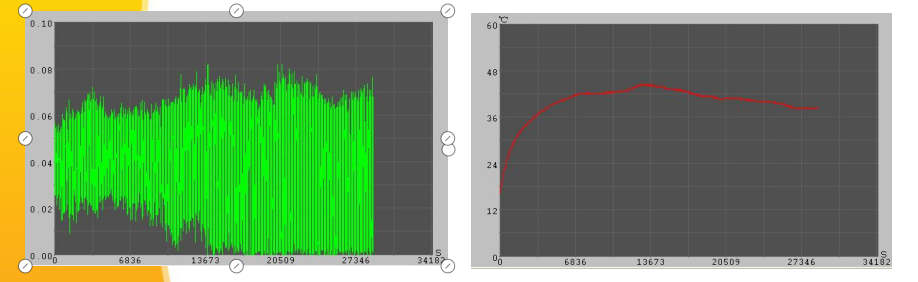

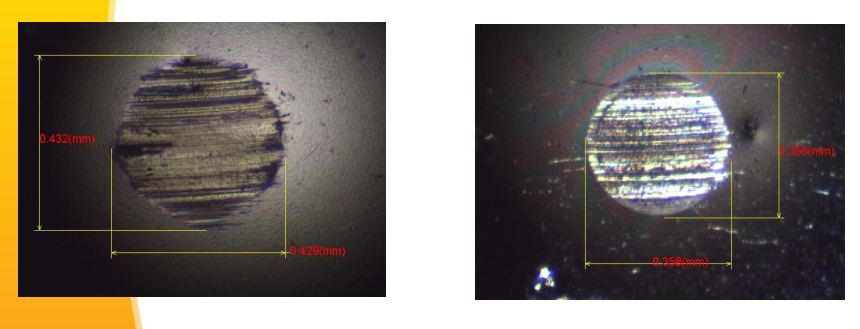

- The friction coefficient of four-ball machine is about 0.02, and the diameter of wear spot is less than 0.3. The small-scale simulated anti-grinding machine can bear 12 mounds, obviously relieves the burning oil, improves the power obviously, and has remarkable oil-saving effect.

The organic nitrogen molybdenum lubricant forms a kind of physical and chemical adsorption film on the friction surface under the normal condition of lubricating parts. Under high-speed, high-temperature and high-pressure conditions, Mo penetrating layer and eutectic rolling lubrication layer are formed on the surface of friction pairs. Due to the spherical shape of itself and the characteristics of high-temperature resistance, toughness and super lubrication, is characterized by high-speed, high-temperature, high-pressure and so on. Turn sliding friction into rolling friction. It greatly reduces the wear and tear between parts, such as anti-wear, anti-friction, wear mark repair and so on, which are difficult to achieve by other substances. This new unique lubrication structure is the first to create a chemisorbed film, a special element.

- The minimum friction coefficient can reach 0.0225 and the wear spot diameter can reach 0.31mm.

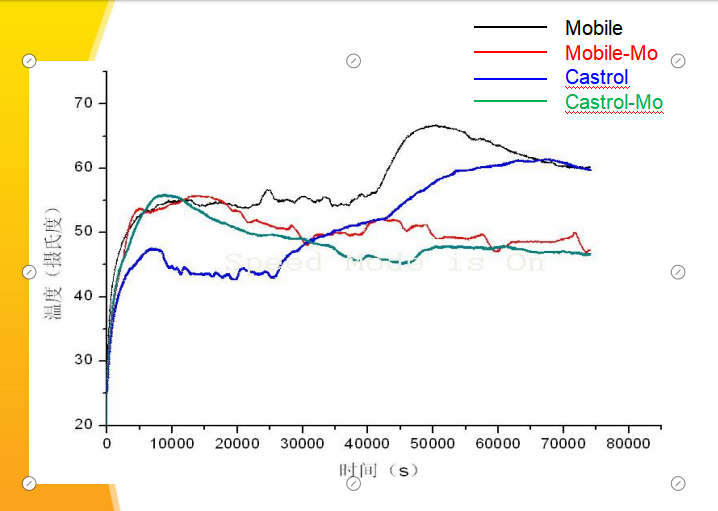

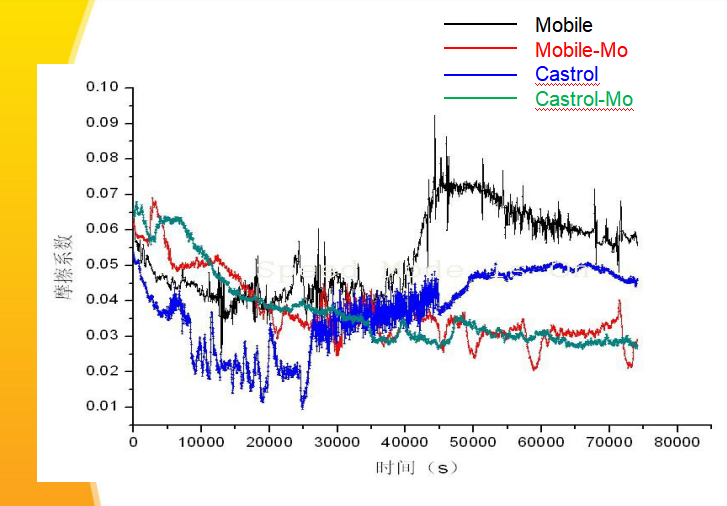

Four-ball machine friction coefficient and temperature change detection chart: 40KG, 9 hours, it can be seen from the diagram, organic nitrogen molybdenum fullerene lubricant with the change of time, the average friction coefficient is basically unchanged; However, with the change of time, the temperature decreases gradually, which indicates that eutectic rolling lubrication will occur with the increase of time.

To form a unique permeable layer that protects the engine from abrasion, good lubricity, and temperature drop from the highest

- Adding additive , the temperature of oil is more than 15 ℃ lower than that of non-organic molybdenum nitride oil.

- Use additive in Mobile and Castrol, The friction coefficient is 1 / 2 of the friction coefficient of the non-organic molybdenum nitride oil.

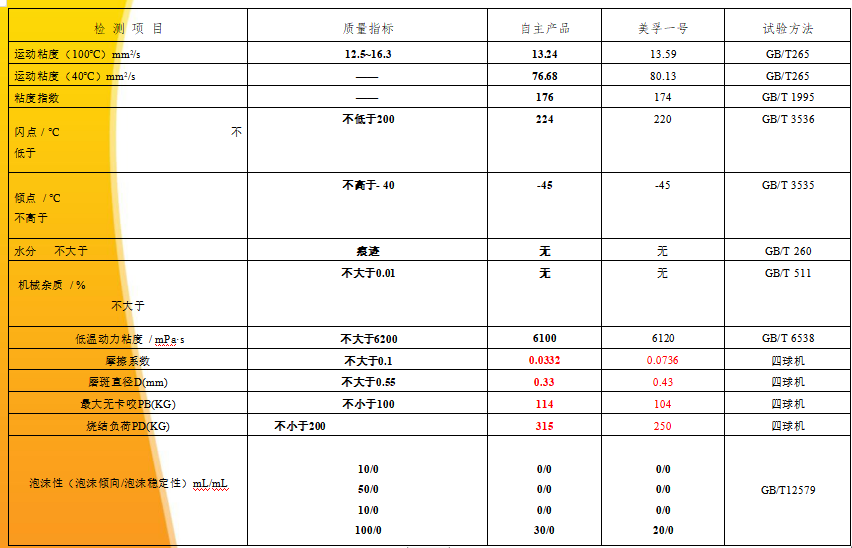

- Comparison of SN 0W40 usage in the Mobile engine Oil

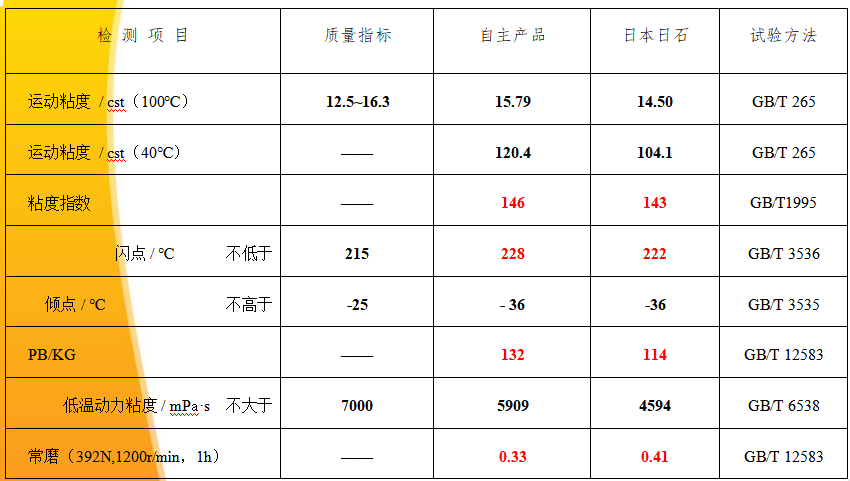

- Comparison of CH-4 15W40 Technology for ENEOS Diesel engine Oil

- The Technical comparison of the fourth Generation Locomotive Oil

- Dissolved in various engine oils in the form of liquid ions, the international API formulation has remarkable fuel-saving effect and obvious power enhancement.

| Item | Quality Index | Test Method |

| Appearance | Deep Yellow | Visual measurement |

| Kinematic Viscosity( 40 ℃),mm 2 /s | 35.3 | GB/T265-88 |

| Kinematic Viscosity( 100 ℃),mm 2 /s | 5.3 | GB/T265-88 |

| Flash point(Open cup ,℃ | 215 | GB/T3536-2008 |

| Pour point,℃ | -18 | GB/T3536-2006 |

It is recommended to be used in diesel engine oil, gasoline engine oil and gear oil as reinforcing agent; the repair agent with self-repairing effect in the rear market of automobile; the power sense is greatly improved, and the friction coefficient can be greatly reduced.

It can obviously inhibit the increase of oil temperature, prolong the oil exchange cycle, and have long-term continuous lubrication effect and outstanding high-temperature anti-oxidation function.