Jun - 05

2015

2015

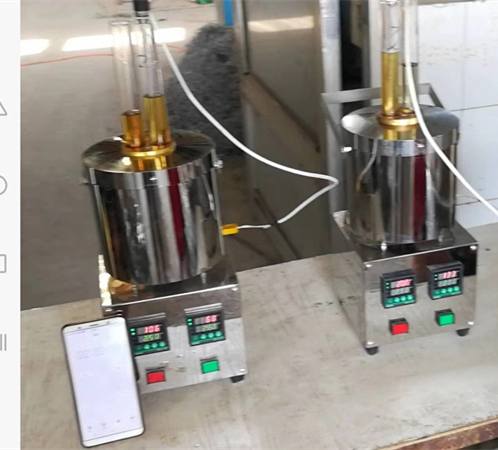

High temperature engine oil testing machine

topech

High temperature engine oil testing machine

Insulation gloves should be worn throughout the experiment to prevent burns

Testing the carbon deposit, viscosity, boiling point, oxidation resistance, and acidity test at high temperature

1. Check all the connections of the instrument (power cord, temperature sensing rod, when the temperature sensing rod is inserted, pay attention to the positive and negative poles. Do not connect the reverse polarity. The easiest way is to look at the plug and the screw on the socket in the same direction).

2, turn on the power, set the heating temperature according to the requirements, the temperature only needs to set the temperature table on the left (the instrument has two thermometers, the temperature meter on the left is set the temperature of the instrument, the green number on the left is the instrument Set the temperature, the red number on the top left shows the instantaneous temperature of the instrument; the temperature meter on the right does not need to be set, and the red number shows the instantaneous temperature of the lubricant in the test tube. This step is very important.

3. Add the lubricant to be tested in the test tube (the contrast oil and the test should be clearly marked). The depth of the oil is about 2/3 of the test tube.

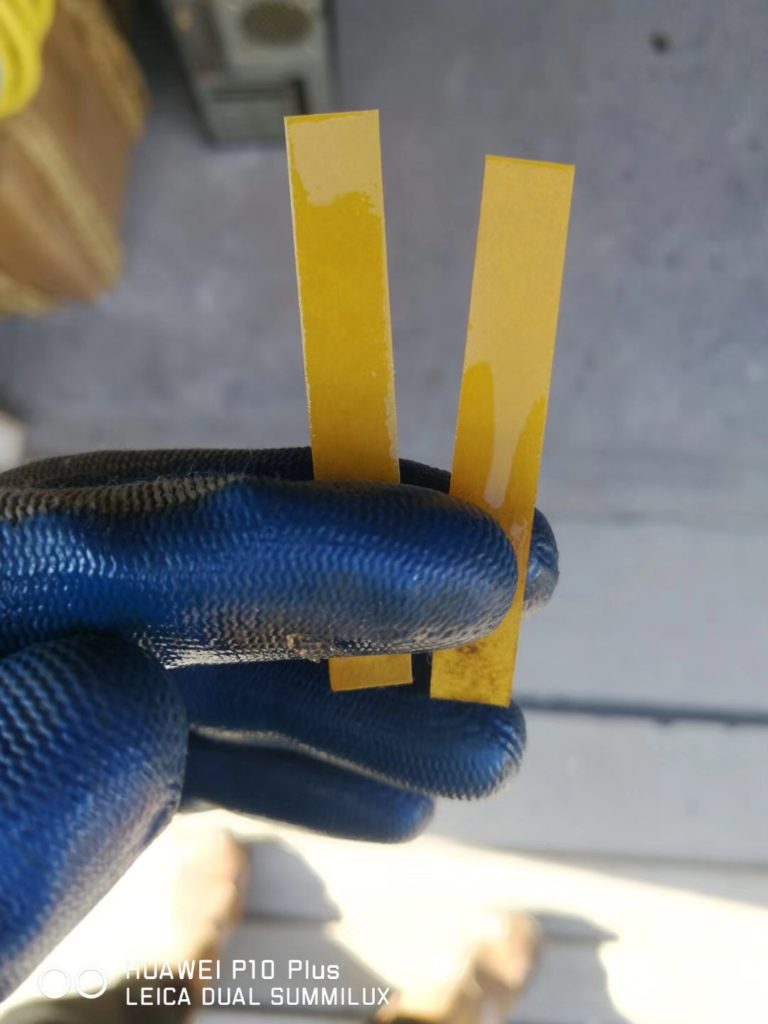

4. Add a copper rod to the test tube.

5. Insert the temperature sensing rod into the oil to be compared.

6. Turn on the power and start heating.

7. Record the time and temperature at which heating begins.

8. During the heating process, carefully observe the changes in the oil in the test tube, and record the time and temperature at which the oil starts to bubble.

Observe the change of the copper rod. In the process, the oil of the copper rod discoloration will definitely be acidic at high temperature. This kind of lubricating oil definitely has poor quality.

9. Observe the time and temperature at which the lubricant begins to bubble during the heating process, and note this time and temperature, then observe the time and temperature from bubbling to boiling, and note this time and temperature. The lower the boiling point, the worse the quality of this lubricant, and vice versa. The shorter the time, the lower the boiling point indicates that the quality of the lubricating oil is worse, and the worse the viscosity of the lubricating oil is, and vice versa.

10. Observe the time and temperature at which the lubricating oil starts to change color during the heating process, and record the time and temperature. As long as the color of the lubricating oil turns black during the heating process, it means that the lubricating oil will definitely be added to the car. The accumulation of carbon indicates that the quality of the lubricating oil is not good, and vice versa. The discoloration of the lubricating oil during the heating process indicates that the lubricating oil has poor oxidation resistance, and vice versa.

11. Turn off the machine and the experiment is complete.

note:

After the experiment is finished, pour the water and pour it into the water. After cleaning, use the detergent and our cleaning tool to clean the test tube as soon as possible.