2012

Strong anti-wear agent/nano anti friction oils additive

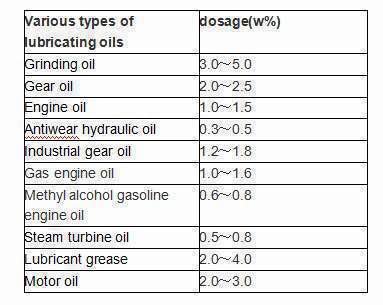

The strong antiwear agent is made from a variety of components, easily in the friction surface of the metal surface to form a permeable layer and chemical reaction film to resist the friction metal in the boundary under the conditions of direct contact with the formation of friction and wear, improve lubrication Quality, reduce friction caused by a series of adverse effects.

The strong antiwear agent contains nanometer material, which spreads and disperses on the metal surface to form the diffusion layer and the permeation layer. The lattice defects and the machining defects of the metal surface are carried out at the instantaneous high temperature (flash temperature) and high pressure Surface conditioning, and change the metal surface structure and shape, and ultimately together with the friction metal to form a hard and smooth metal anti-wear layer, thus overcoming the friction brought a series of adverse effects, to extend the life of equipment to extend the life of lubricants , Save energy, reduce friction heat, reduce noise, reduce vibration and other purposes.

| Item | Quality Index | Test Method |

| Appearance | Very light yellowish liquid | Visual measurement |

| Density(20℃)/(kg/m3) | 1.15-1.18 | GB/T1884/1885 |

| Kinematic Viscosity(100℃)/(mm2/s)

(40℃)/(mm2/s) |

11-13

120-130

|

GB/T265 |

| Flash point(Open cup)/℃ ≥ | 213 | GB/T267 |

| Pour point/℃ | -20 | GB/T3535 |

| Heating loss (125℃,3h)/% | 0.10-0.14 | GB/T7325 |

| Copper corrosion(121℃,3h)/ ≤ | 1 | GB/T50961 |

| Load bearing ability | 4150 lbs | |

| Coefficient of Friction(COF) | 0.037 Dynamic | |

| Anti Friction area(mm) and Performance improved percent (%) | 0.35mm/ 83% | |

| Four ball machine test PB/N | 1200 | GB/T31421 |

Agent function:

(1) Save 5-10% on fuel, steam and diesel consumption.

(2) save oil, oil extended oil period of 1-3 times.

(3) protect the machine, extend the overhaul mileage of motor vehicles and motorcycles more than 1 times.

(4) increase power, engine power increased by 8%.

(5) Reduce pollution, reduce tail smoke, reduce emissions by 50% or more.

(6) shock absorption, noise reduction of about 5-15 dB.

(7) low temperature start, can be used at -30 ℃.

(8) to reduce temperature rise, the engine working temperature is reduced by about 10 ℃.

Precautions for storage and use:

◊ Packaging, labeling, transportation, storage, delivery and acceptance as per SH/T0164

◊ Nonflammable,nonexplosive and noncorrosive

◊ Should be stored in dry, ventilated, 45 ℃ below the Treasury; blending temperature should not exceed 75 ℃.

◊ Feed and use procedures should be carried out in general concentrated chemicals precautions to avoid contact with the skin. Once touched, rinse with soap and water

Anti friction test performance more than 21pcs weights with nano oil film on abrasive wheel

https://www.youtube.com/channel/UCuyBLp2UHPNm3VH_PpYO8zw?view_as=subscriber

Dear All

Hi

Interested by your Tribo additive anti-wear AND anti-friction concentrated 100% that I will dilute with base oil 5 grammes of your 1gr solid concentrated additive needed for one liter crancking-oil ) Engine oil)

All my best for your concentrated additive pricing

regards

It works really well for me